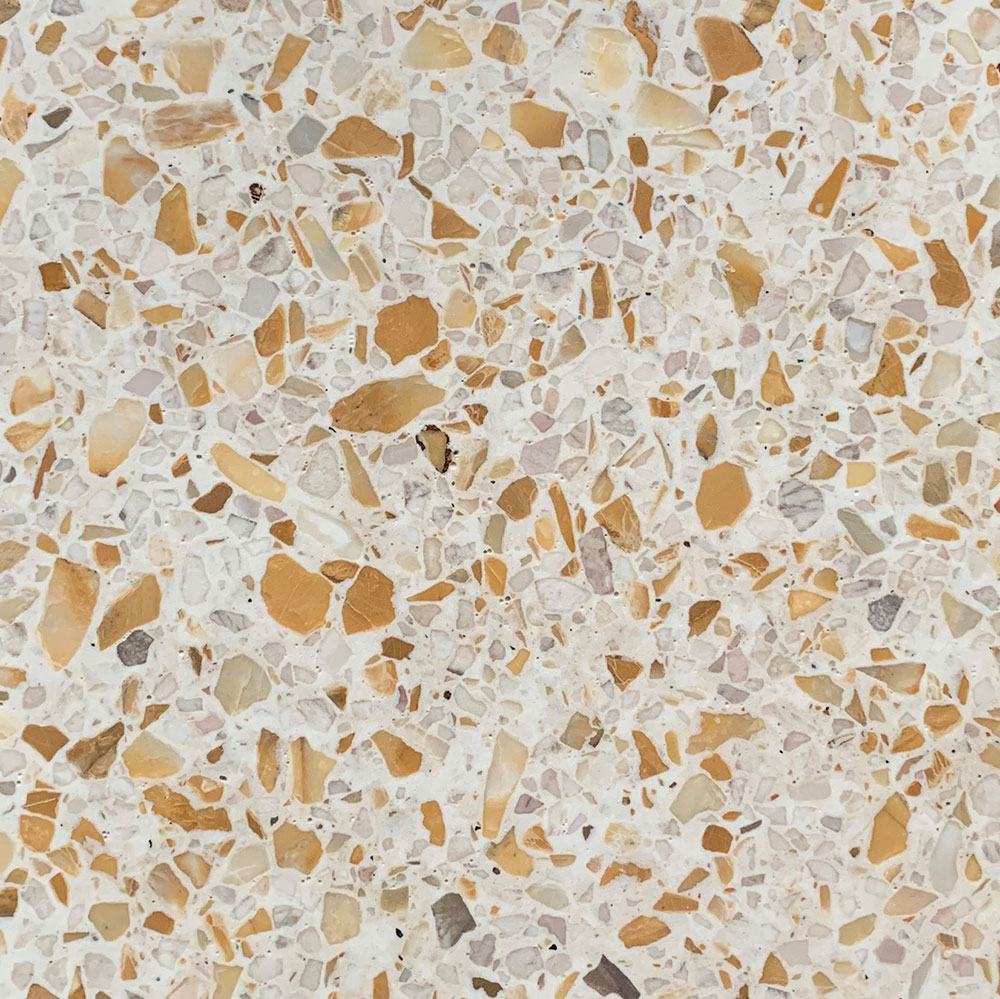

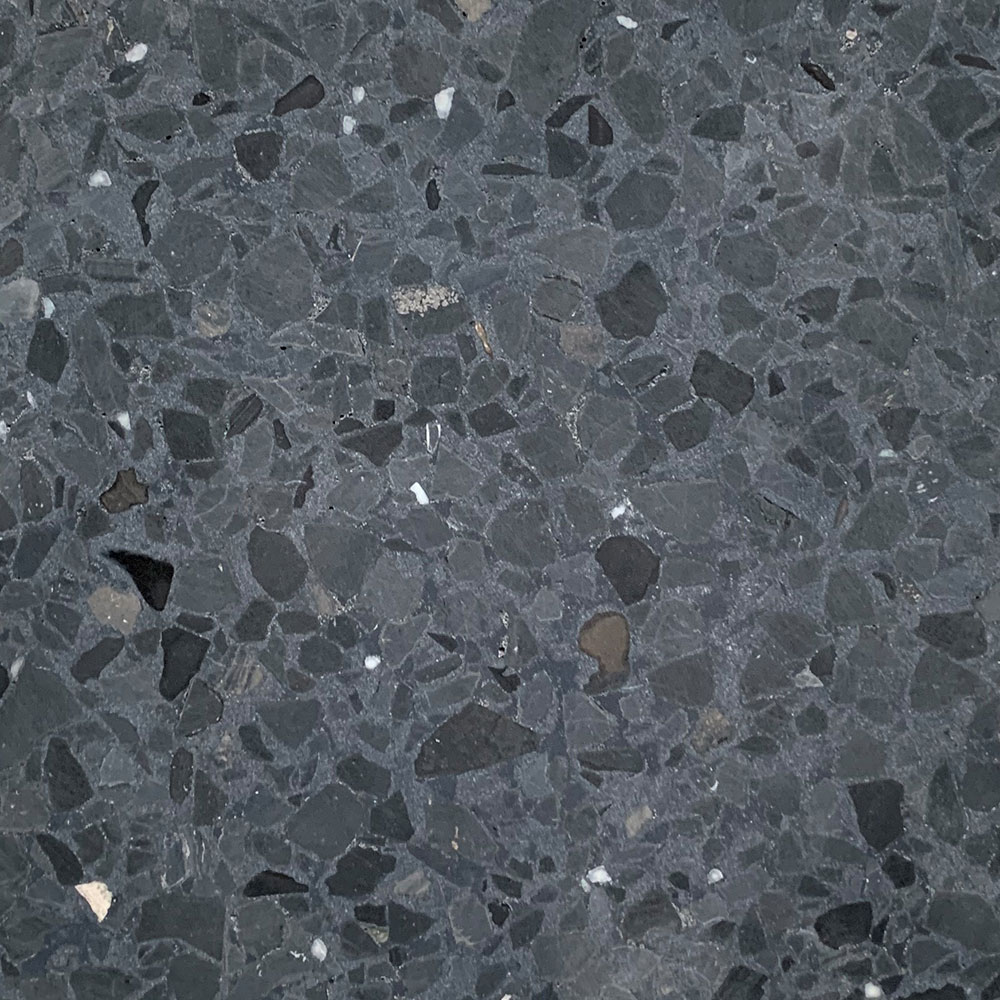

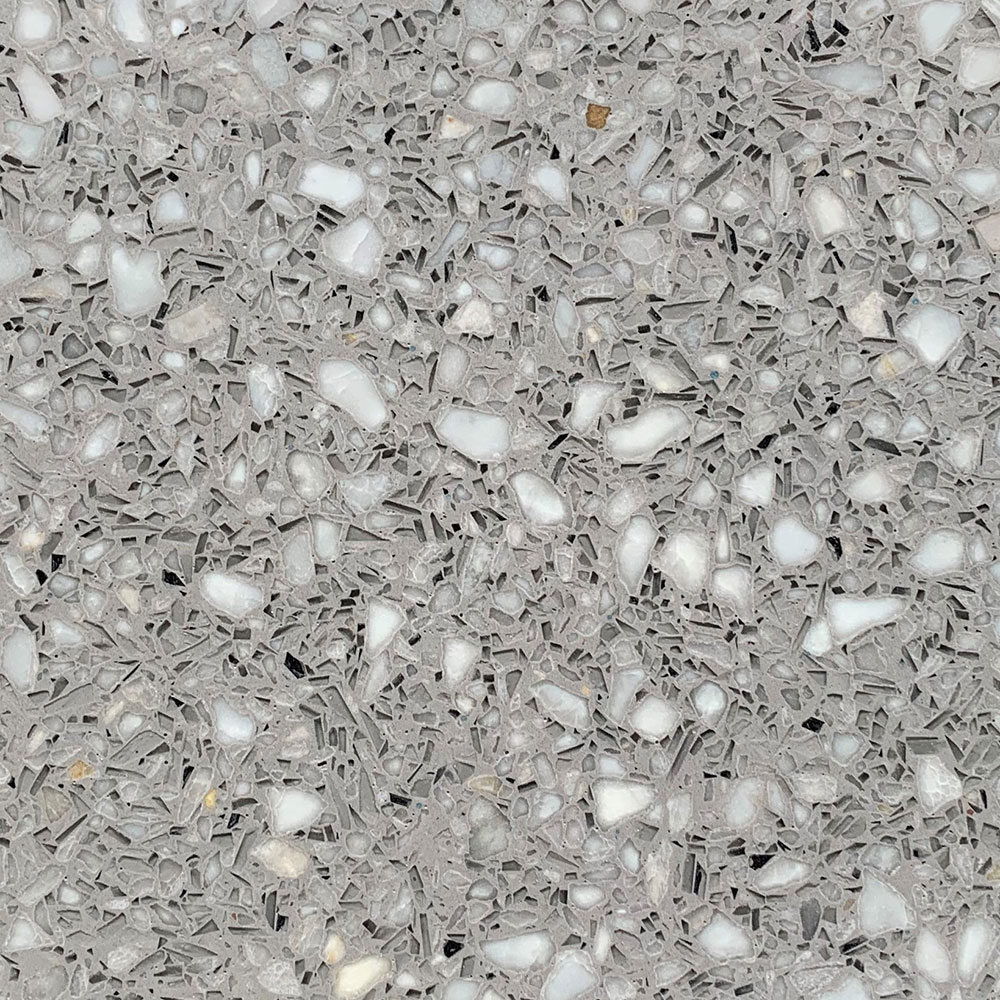

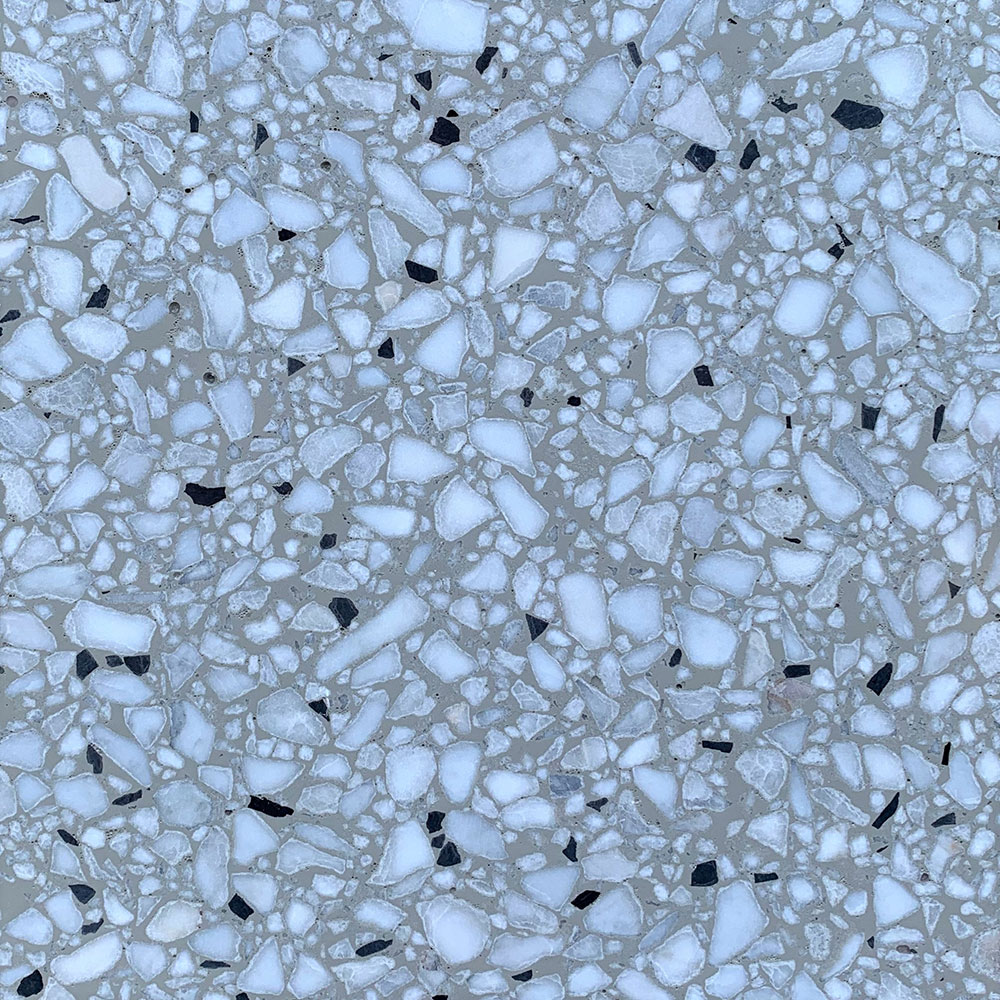

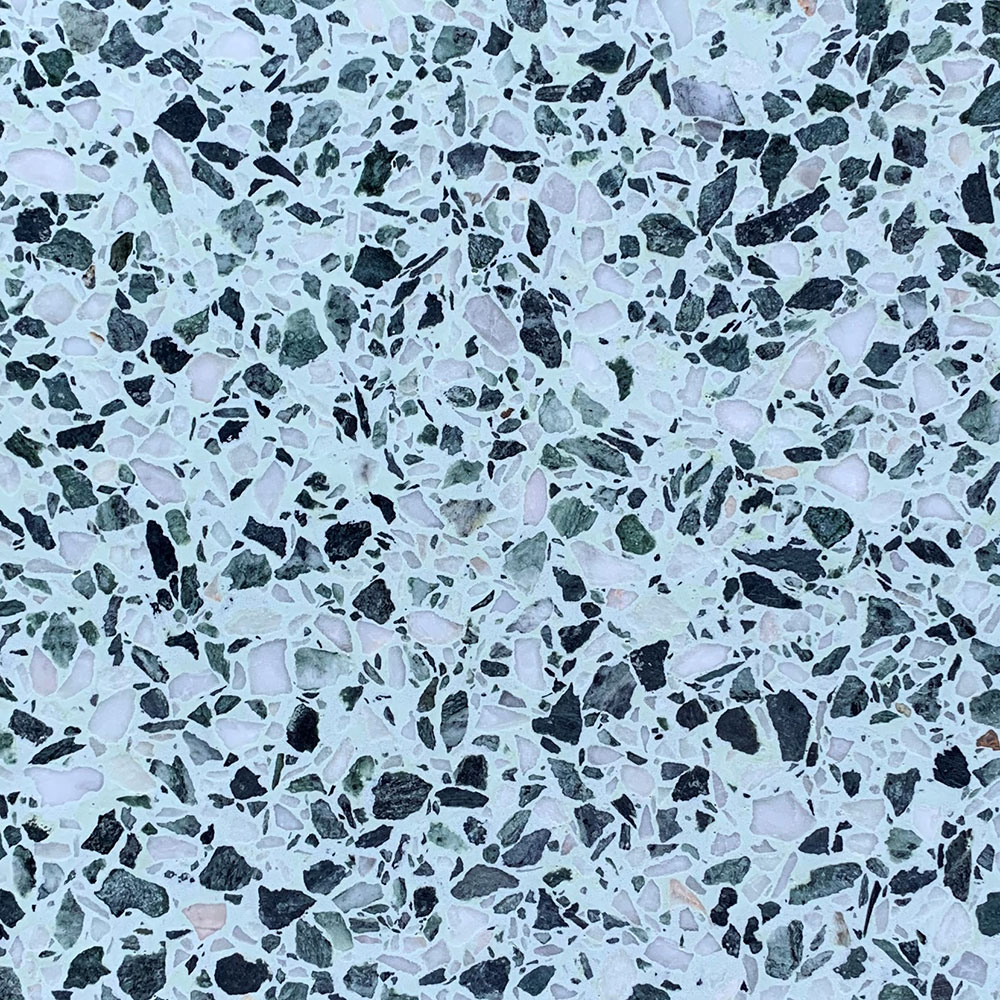

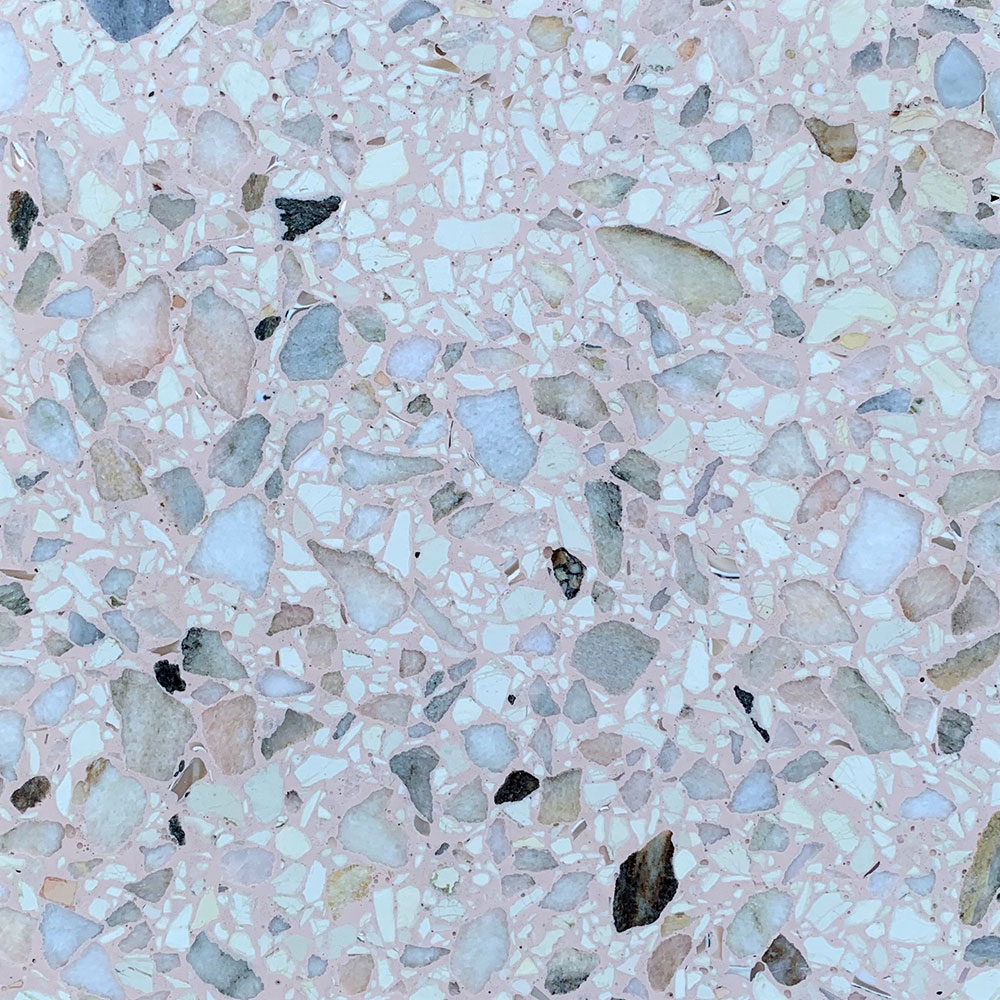

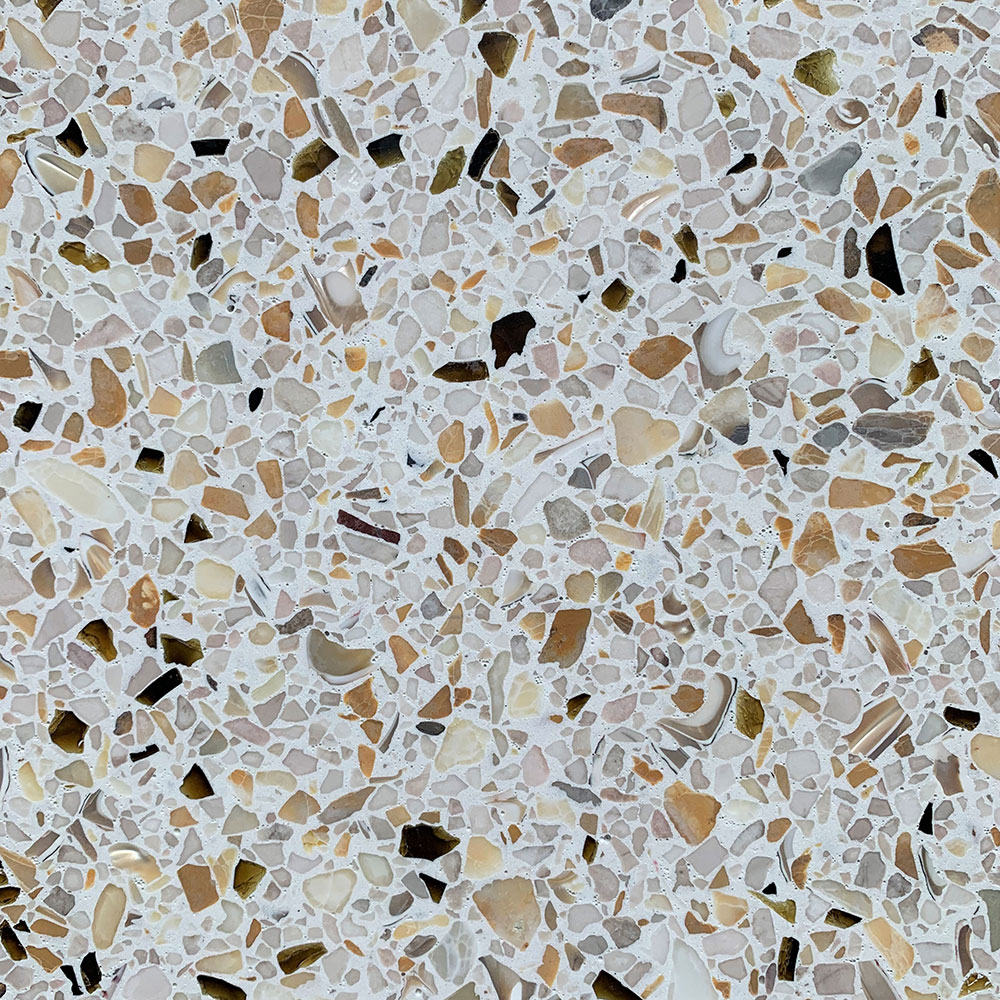

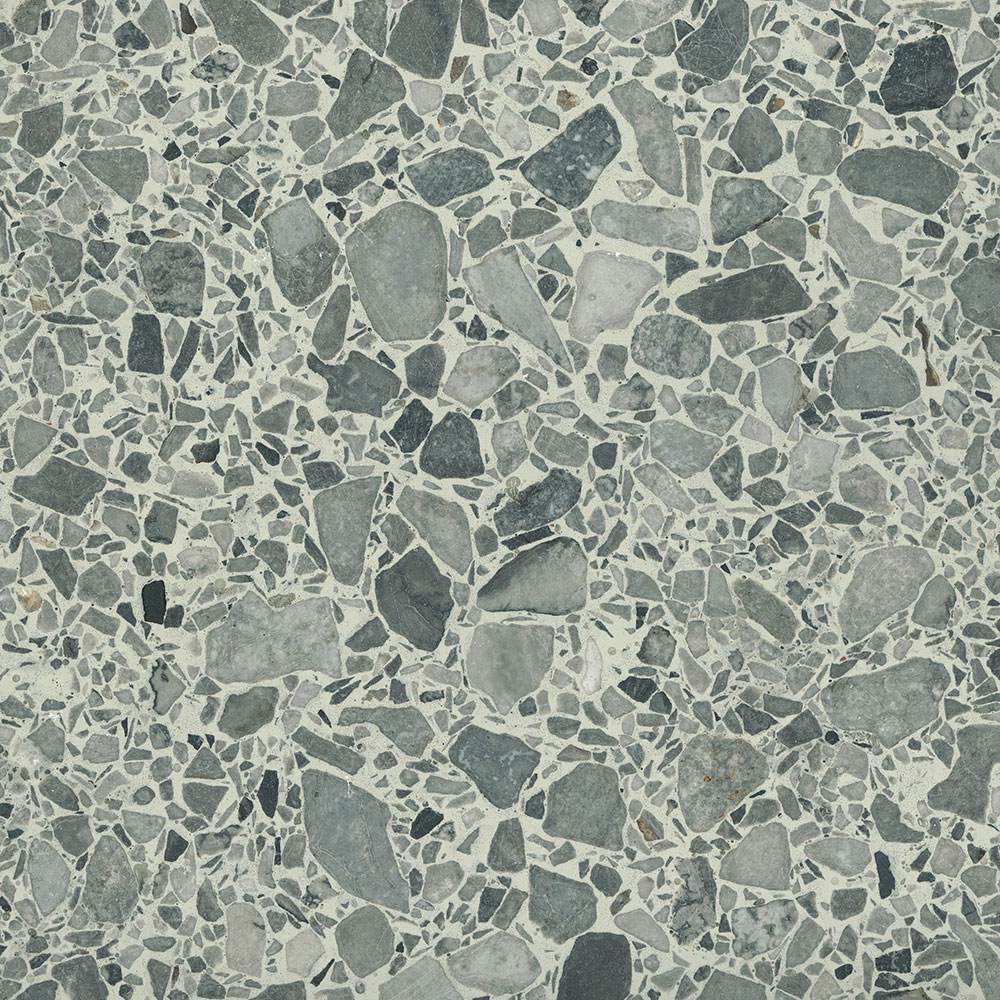

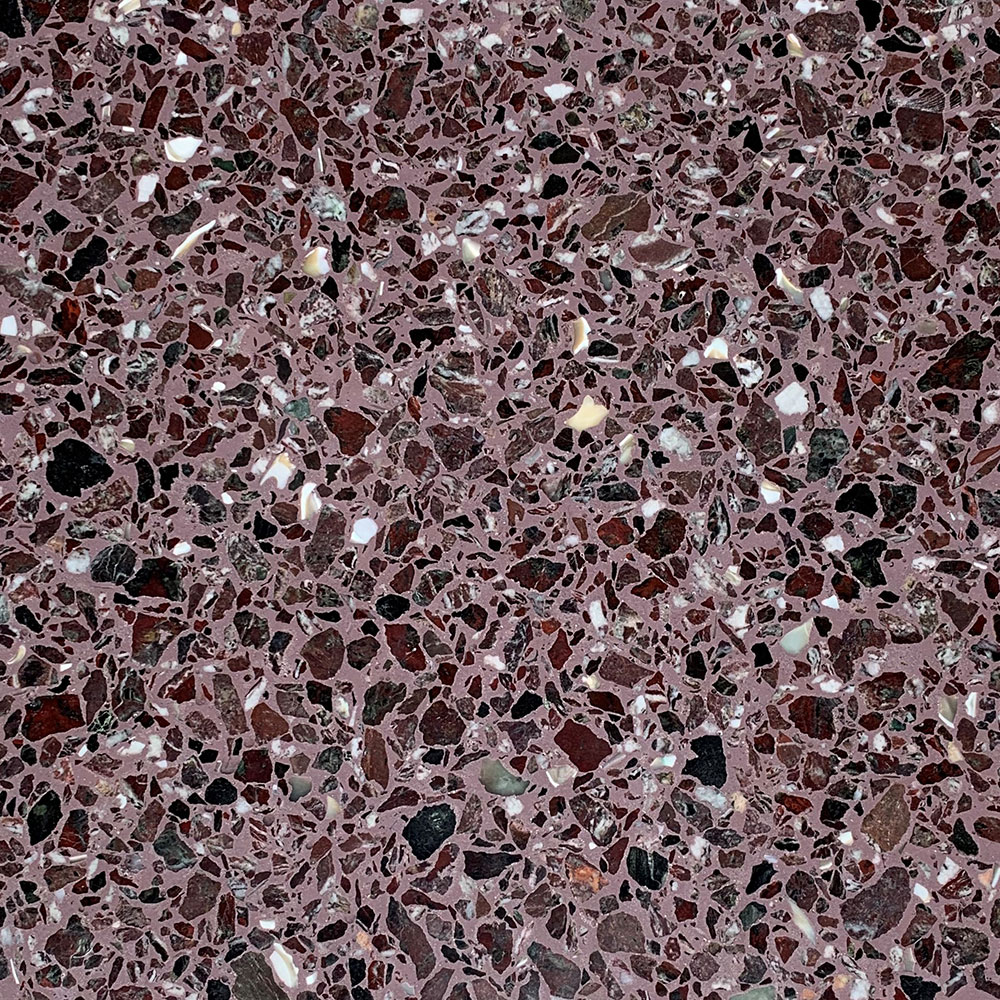

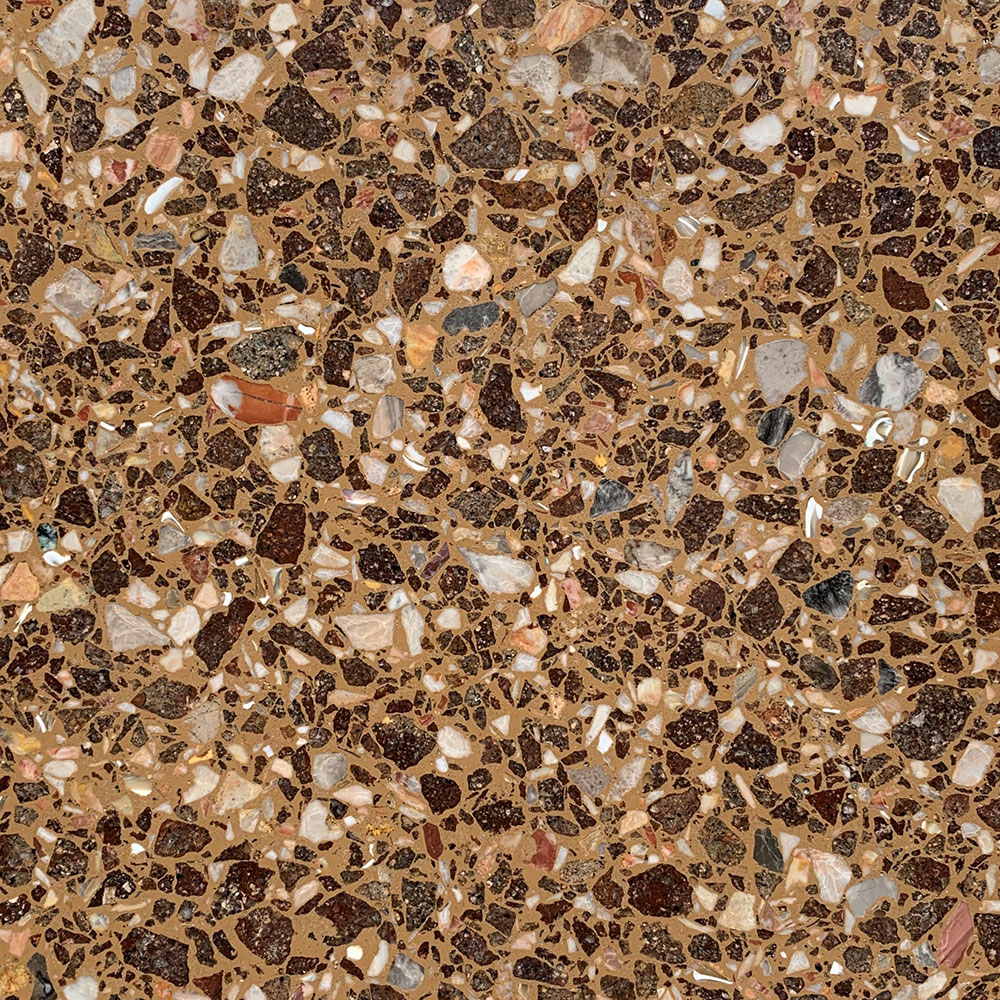

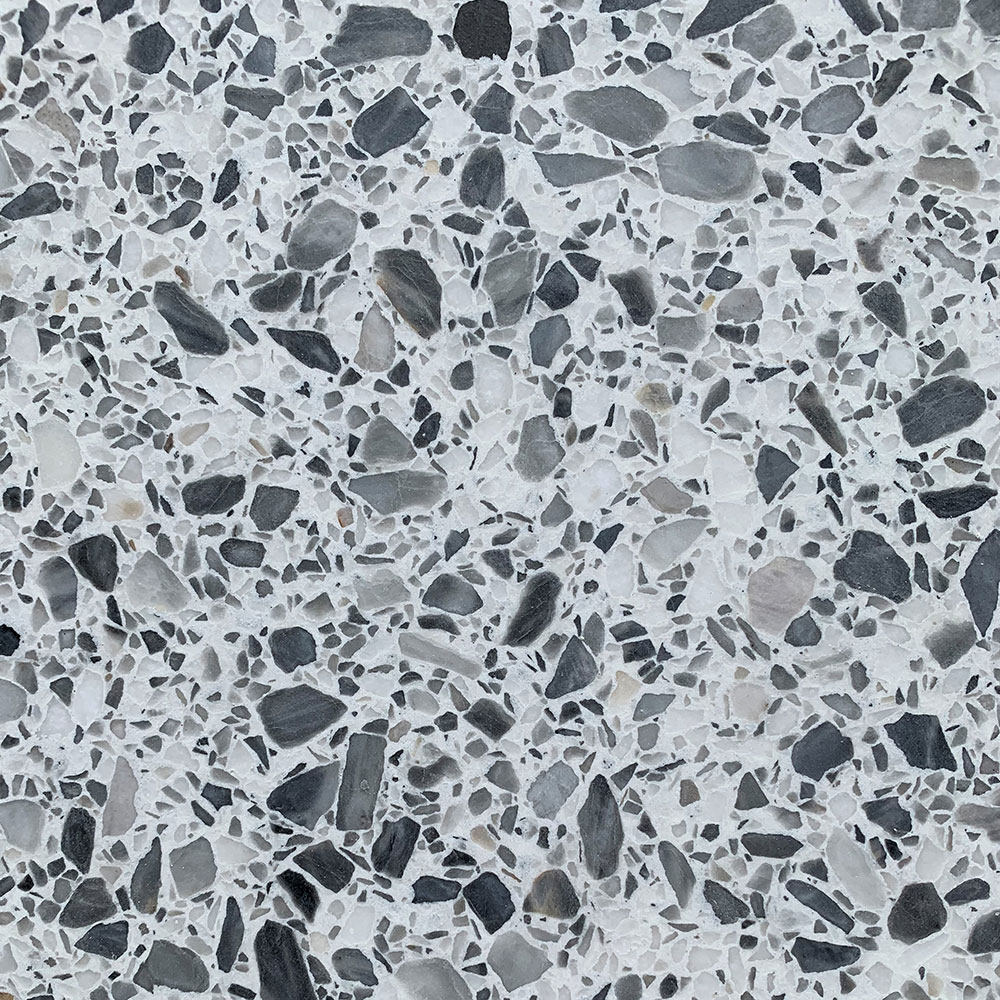

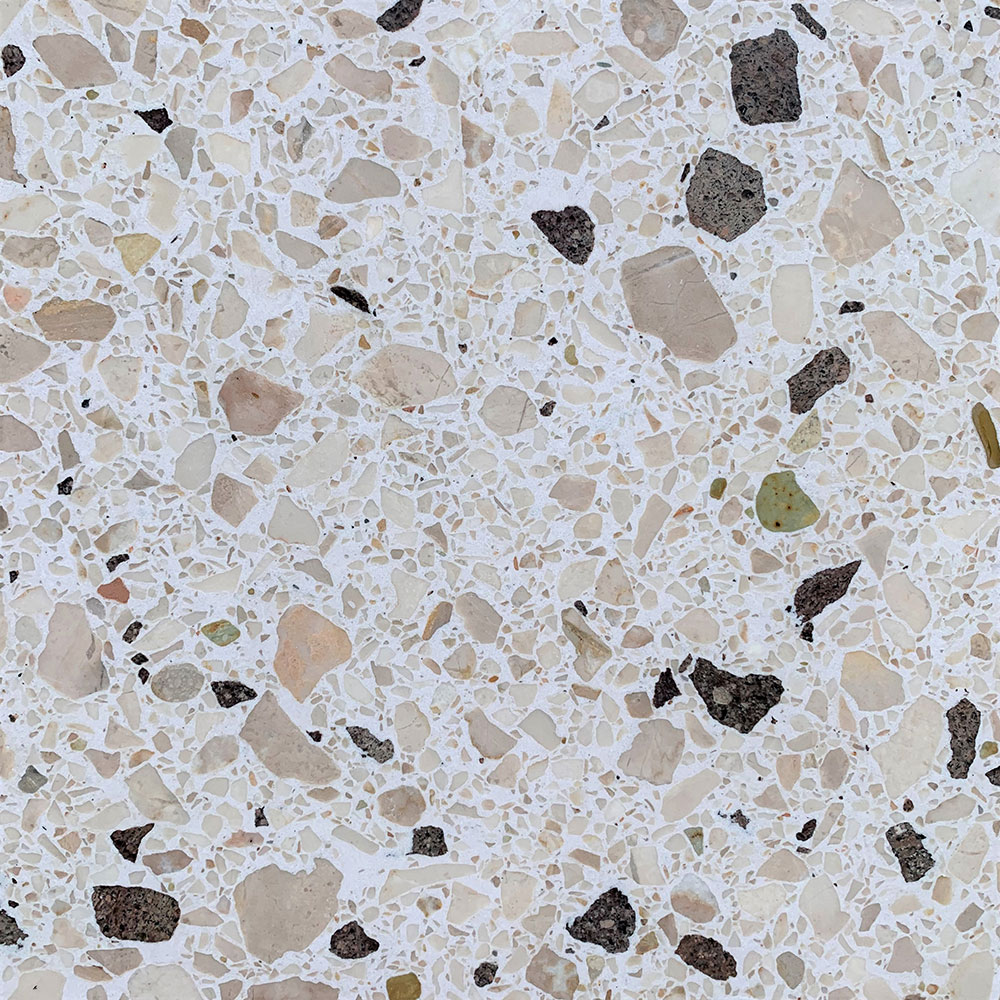

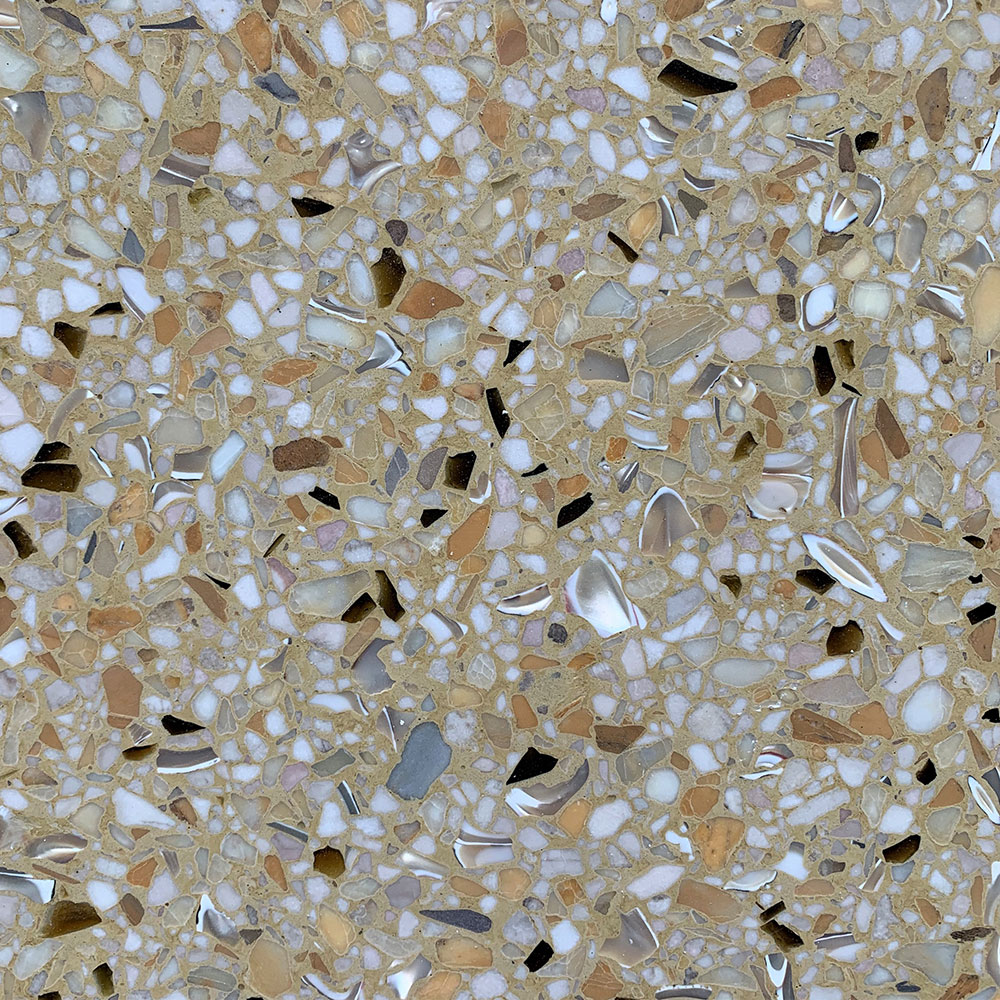

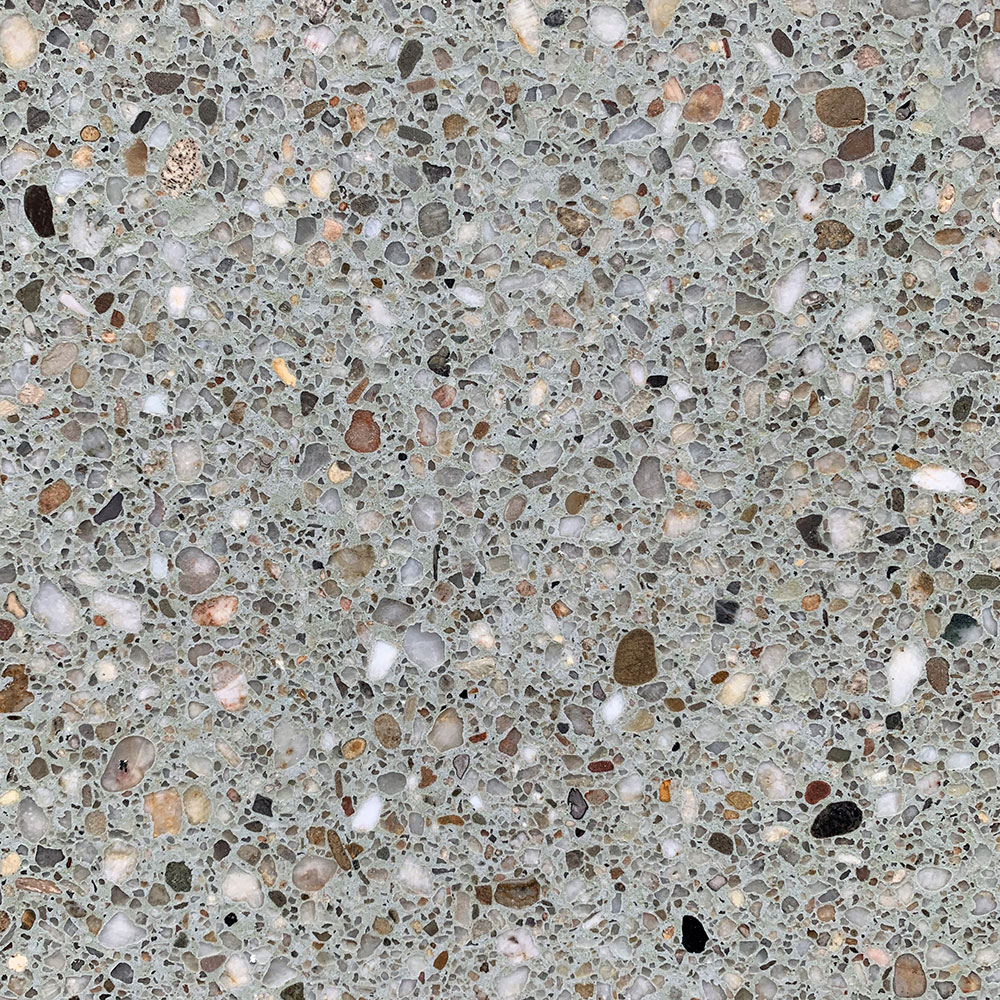

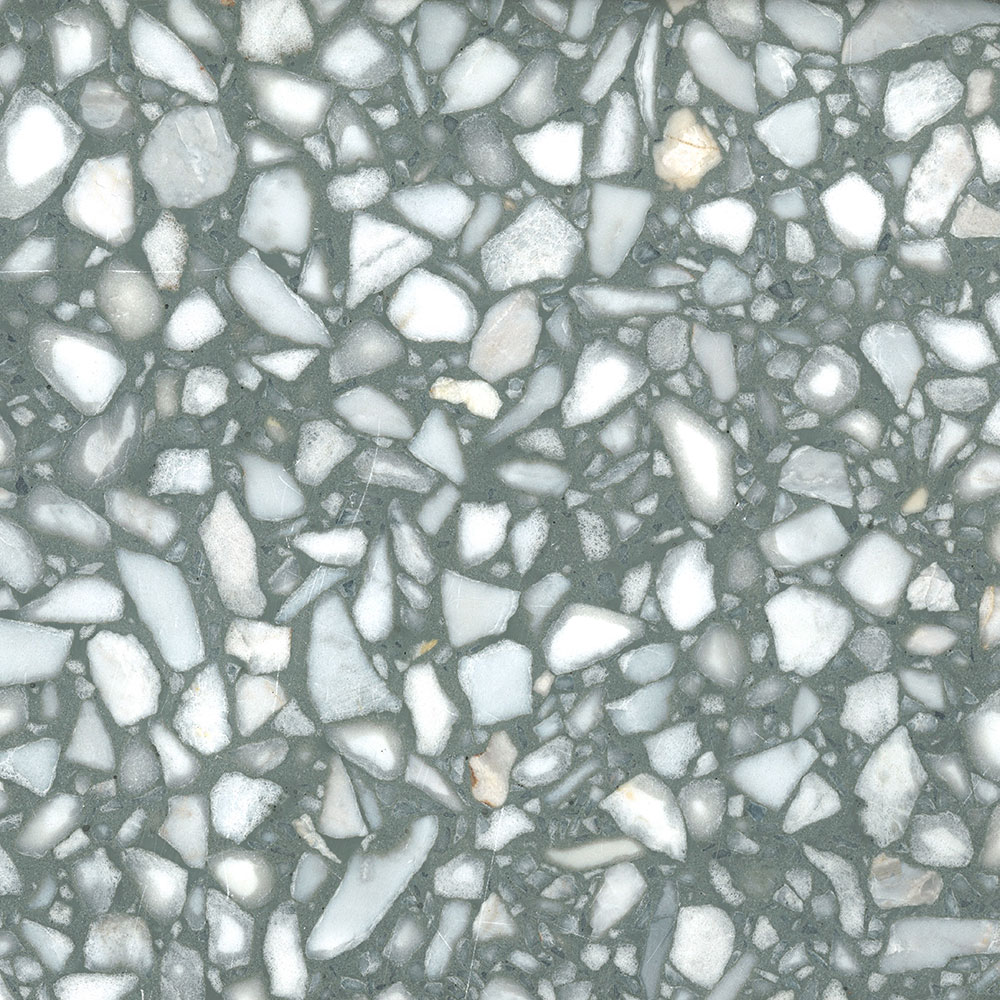

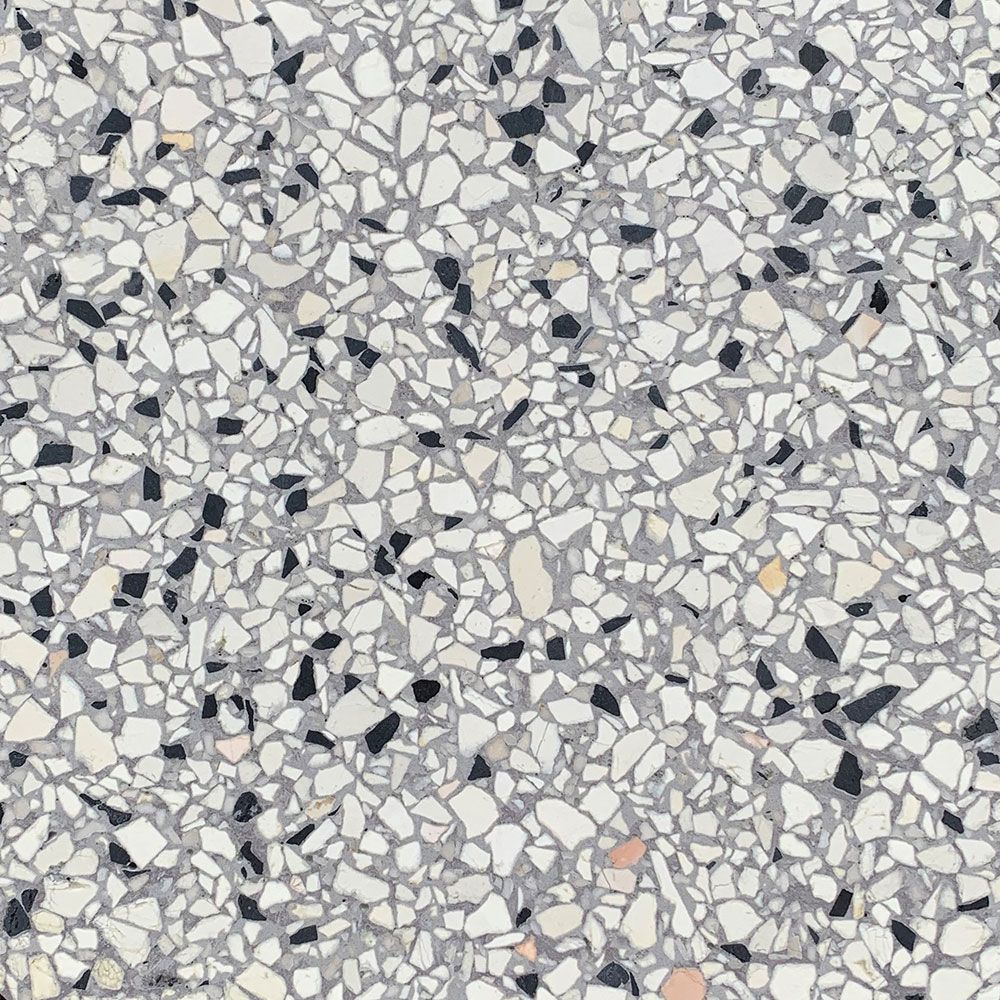

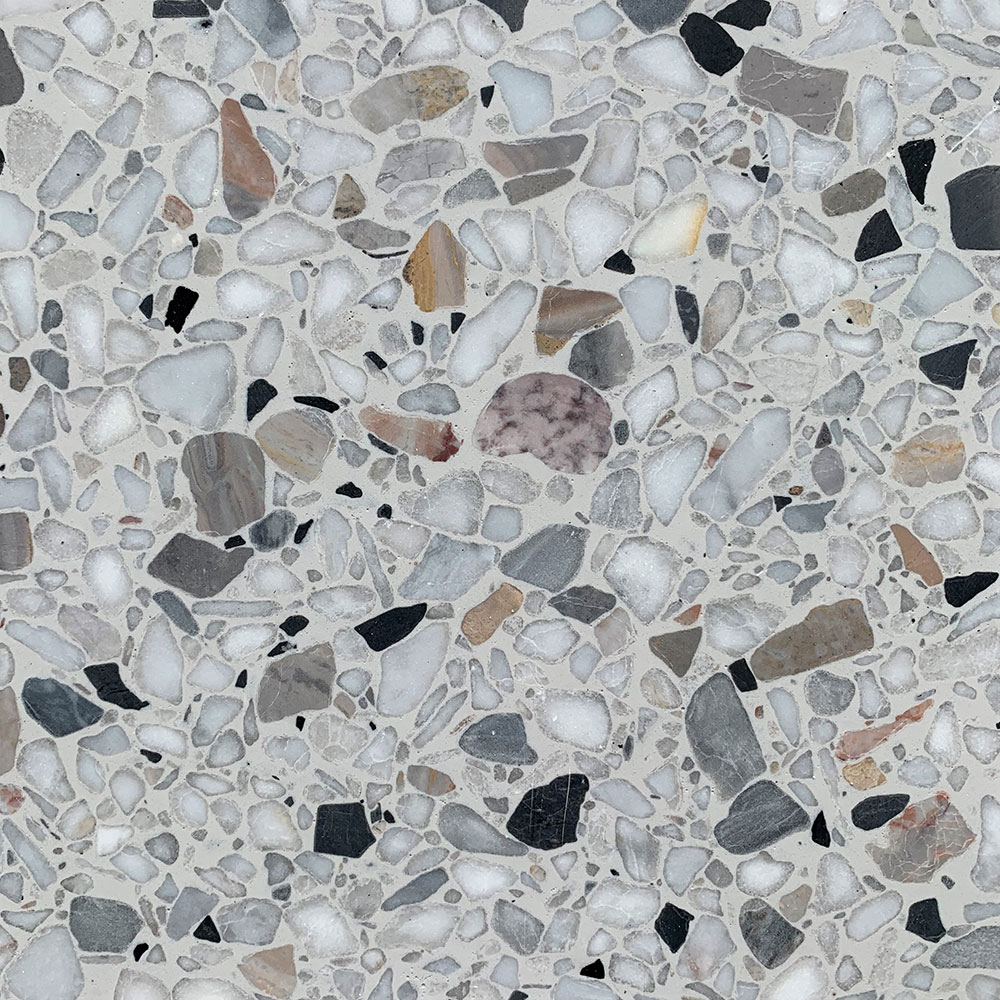

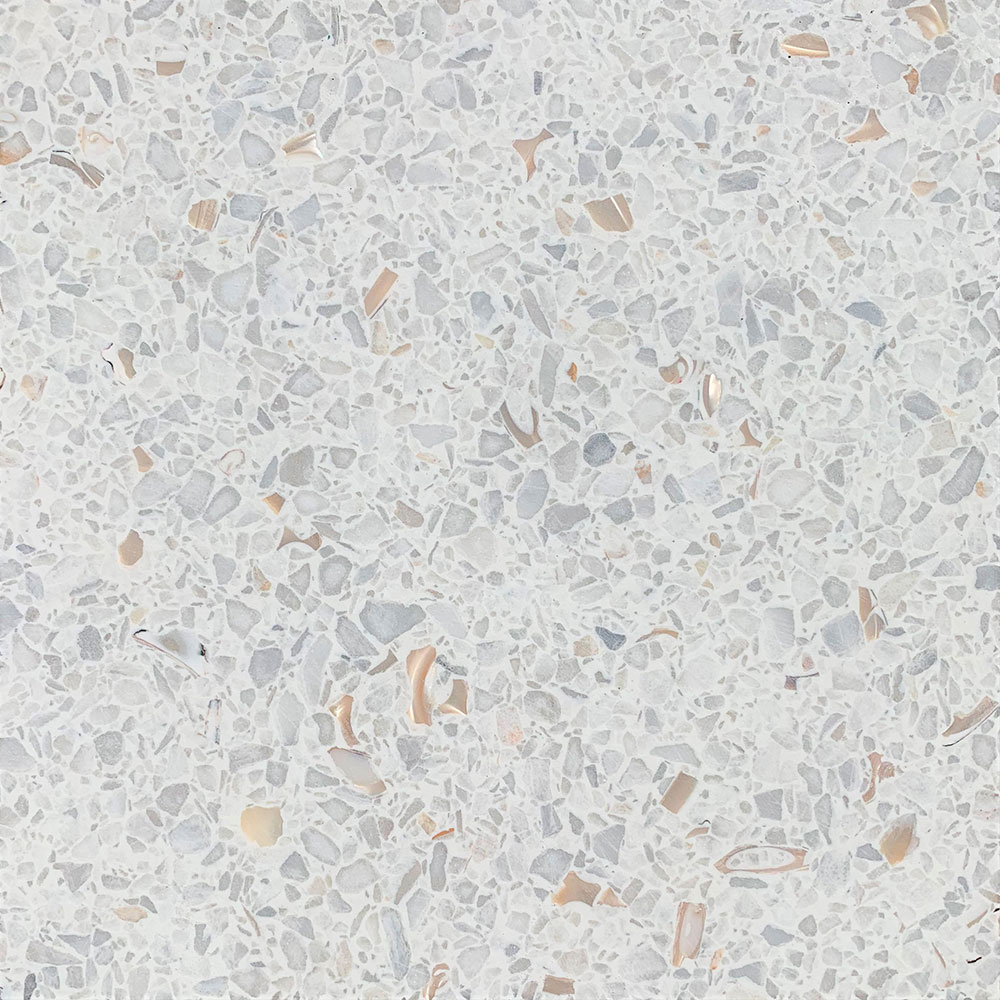

A sustainable, seamless and flexible terrazzo flooring made up of rapidly renewable resources that are free of ortho-phthalates, chlorine and solvents. Durabella has exceptional characteristics in appearance, aesthetics and durability – a decorative floor finish, with endless customizable designs including logos, unique patterns and intricate designs. The overall construction is not vastly different from that of traditional Terrazzo, though the ingredient makeup is very different.

Durabella is extremely durable and perfect for any high traffic area such as hospitals, airports, theme parks, schools, etc. Our terrazzo does not use epoxy or any harsh chemicals during the installation process. The product is also resistant to water, preventing microbial growth and mold – one of the many reasons it is a great fit for healthcare facilities and any shared public spaces dedicated to creating healthy spaces.

Regular removal of dust and if necessary wet cleaning with a neutral cleaning agent. For further instructions see the maintenance instruction guide.

Duracryl produces floorcoverings based on natural and renewable materials. This has a major advantage on climate change compared with fossil based products.

For accountability of the impact of the carbon footprint of each flooring product we are using the definition of “Healthy Materials Lab at Parsons School of Design” in New York, a leading authority on this subject.

“Currently, there is no universal threshold for ‘low embodied carbon’ in flooringmaterials. After discussing this research with experts, we have set a rigorous standard that can meet 2030 emission goals. These products, labeled with ‘LEC’, embody below 5kg of CO2 per square meter”

All Duracryl products comply with this standard and are referred to as “Climate Positive Flooring”

Duracryl is always available if you have any questions about your flooring or need help making your choice. Please see our CONTACTFORM.

The various Duracryl collections offer endless possibilities for versatile and creative floor design. The different colours, embossings and applications are beautiful on their own or can be combined for stunning results.

Take a closer look at the following links: